From design to reality

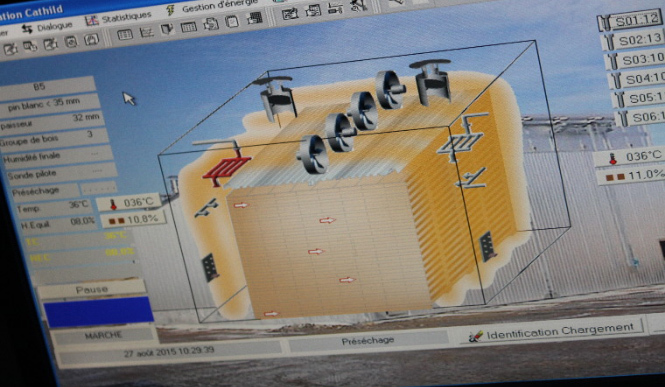

The Matra Group’s commitment to quality begins right away, during the CAD design stage. Once the CAD drawing is approved, it’s used to fabricate wood components that meet the customer’s quality and packaging criteria. It becomes a key tool that’s used in every step of the process to create a finished product that’s entirely to spec.